Industrial Large Spatial Model for Real Operations

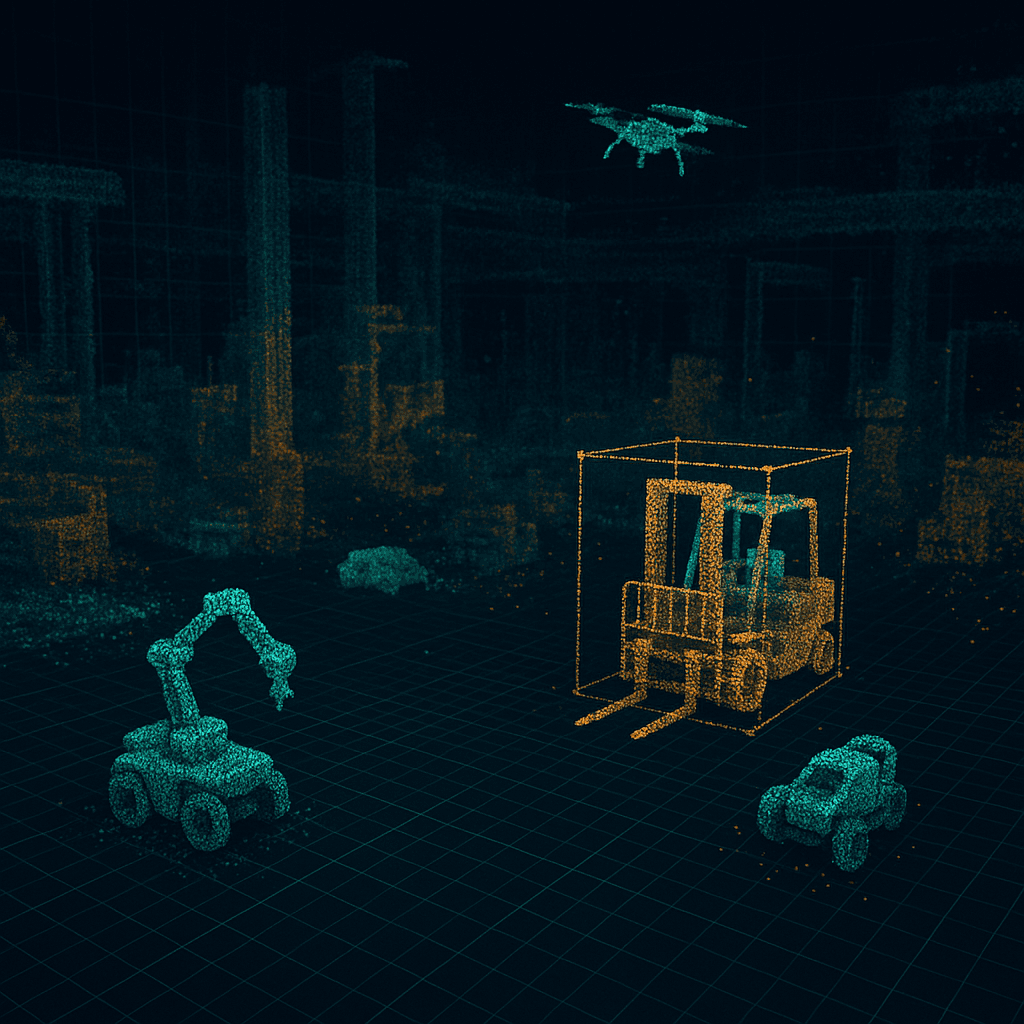

Building an industrial Large Spatial Model that learns 2D/3D data and infers process-critical information for logistics and manufacturing.

Our expert consulting team will propose the optimal solution tailored to your requirements.

Plug-and-Play Robot AutomationLogistics & Manufacturing Innovation

Ready-to-deploy 3D spatial intelligence robot automation solution with no custom development required. Proven innovative technology first chosen by major domestic automotive manufacturers, large shipyards, and other enterprises.

Problem Solving

Traditional: Massive costs and time investment required for robot deployment through system integrators with extensive custom development

LiOps: LiOps: Immediate deployment powered by an industrial Large Spatial Model and robotics stack, without heavy custom development.

Technical Advantage

World #1 in 3D Segmentation: Global top ranking in autonomous driving core technology

Vision-based Self-recognition Technology: Revolutionary technology that allows robots to recognize their own body and control in real-time with a single sensor

Core 3D Technologies

Implementing spatial intelligence that understands complex sites like humans with world-class 3D Segmentation technology

3D Segmentation

World #1 3D spatial recognition technology

- Real-time dynamic/static object discrimination

- 99% precise path calculation

- 81% obstacle avoidance performance improvement

3D Registration

CAD file and real object matching technology

- Assembly process progress evaluation

- 100% matching success rate

- Automatic welding line detection

3D Reconstruction

NeRF-based real environment simulation

- Photo/video → 3D data conversion

- 95% simulation success rate

- Significant integration cost reduction

Transparent Object Recognition

Depth information inference technology for transparent objects

- 77% depth error reduction

- Pick & Place error minimization

- 30% → 2% error rate improvement

Industrial LSM Core

A large spatial model that understands industrial 3D scenes and transfers across tasks.

- Self-supervised 3D representation learning

- Multi-task inference across detection, segmentation, registration, and retrieval

- Fast adaptation to new sites and sensors

Hybrid Mapping

Camera + 3D LiDAR fusion technology

- Real environment-based zone setting

- Remote configuration capability

- Easy modification without factory visits

Industrial Large Spatial Model Platform

An industrial Large Spatial Model platform integrating 3D Segmentation, Registration, and Reconstruction. It learns spatial context from 2D/3D inputs and infers process-critical information for real operations.

Battle-tested Solutions

3D spatial intelligence robot solutions first chosen by major domestic automotive manufacturers, shipyards, and heavy industry companies

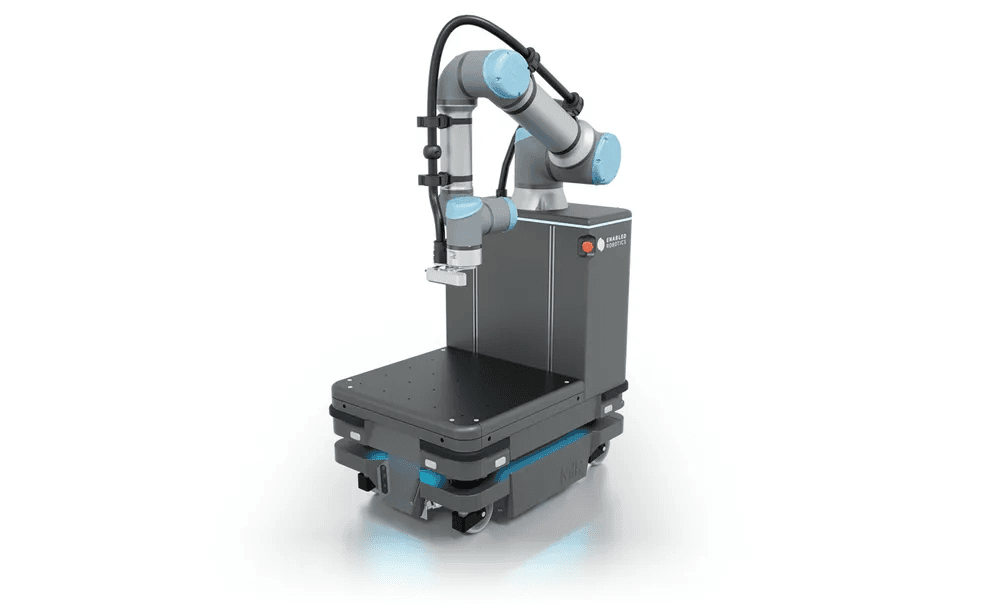

3D AMR Logistics Solution

Complete Pick & Place automation

Key Features

- Annual $12M labor cost savings (56→9 staff)

- 6x faster than manual work (450 picks/h)

- 77% transparent object precision improvement

- Cost recovery within 12 months

Shipyard Automation Solution

Ship component progress tracking & movement timing prediction

Key Features

- 100% PoC success at major shipyard

- Deployment discussions underway with major domestic shipyards

- 3D Registration-based

- Patent application and priority examination completed

Autonomous Forklift

Fully autonomous 3D deep learning forklift

Key Features

- Loading/unloading automation project contracted with major automotive manufacturer

- Free navigation without fixed routes

- 99% precise path cumulative error

- 81% obstacle avoidance performance improvement

3D Welding Automation

Single sensor-based 3D cognition welding robot

Key Features

- Negotiations underway with major heavy industry company

- Superior efficiency vs direct teaching method

- Automatic welding line detection

- 1 person per 2 robots → Complete automation

Proven Results, Guaranteed ROI

With technology verified by major domestic automotive manufacturers and shipyards, investment recovery is possible within 12 months at 30% lower cost than competitors.

Young but Proven Team

Team with first-hand industry experience, targeting global markets with Korea's top 3D Reconstruction and Segmentation technology

Heejoon Park

Co-CEO / CBO

Seoul National University Computer Science, RECON Labs MLOps Engineer, 8-year fullstack developer

Seungyeob Seon

Co-CEO / CAIO

Chung-Ang University Computer Science, Hyundai Mobis Autonomous Driving Researcher, World #1 in 3D Segmentation

Bumgyu Bae

Robotics Lead

Seoul National University Mechanical Engineering, Seoul Science High School, Physics Olympiad Summer School, Biorobotics Lab

World #1 3D Segmentation Technology

Shows significantly superior performance compared to models from global autonomous driving leading companies. Proved the highest level of technology by recording world #1.

contact@liops.aiLet's Build the Future Together

Do you have any questions about AI robot solutions?

Please feel free to contact us anytime.

Contact Information

contact@liops.ai

Phone

+82-10-6743-7876

Address

510-ho, 25 Yeonmujang 5ga-gil, Seongdong-gu, Seoul